Required Tools

Woodworking is inherently dangerous. Your safe operation of the tools below is your responsibility. If you are unskilled or uncomfortable using the necessary tools we recommend finding and hiring a local carpenter to cut the parts for you.

These are what we consider the bare minimum tools for this project. Other tools and methods are acceptable.

Drill/Driver - https://thetoolnut.sjv.io/LPMk2L

Circular Saw - https://thetoolnut.sjv.io/LPMk2j

Framing Square - https://thetoolnut.sjv.io/WDMoNG

Carpenter’s Square - https://thetoolnut.sjv.io/2rvmdg

Tape Measure - https://amzn.to/3TvQpjs

Drill/Driver Bit set (Specifically #2 Philips Bit, 1/8” Drill Bit, #2 Square Bit) - https://thetoolnut.sjv.io/P0MG4z

8ft Straight Edge - https://thetoolnut.sjv.io/QOM1AA

Recommended Tools

Wood Clamps - https://amzn.to/3MFUbVe

Self-Centering Drill Bit - https://thetoolnut.sjv.io/P0MG4z

Corner Assembly Jigs - https://amzn.to/3Vz7I5f

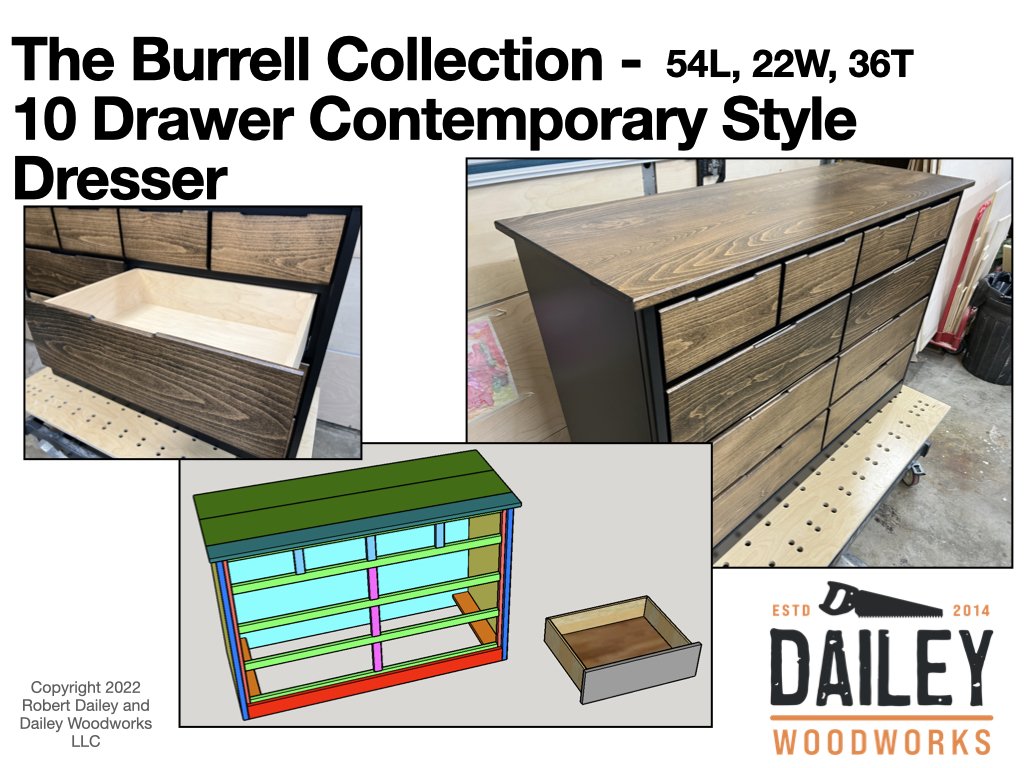

Materials and Cost to Build

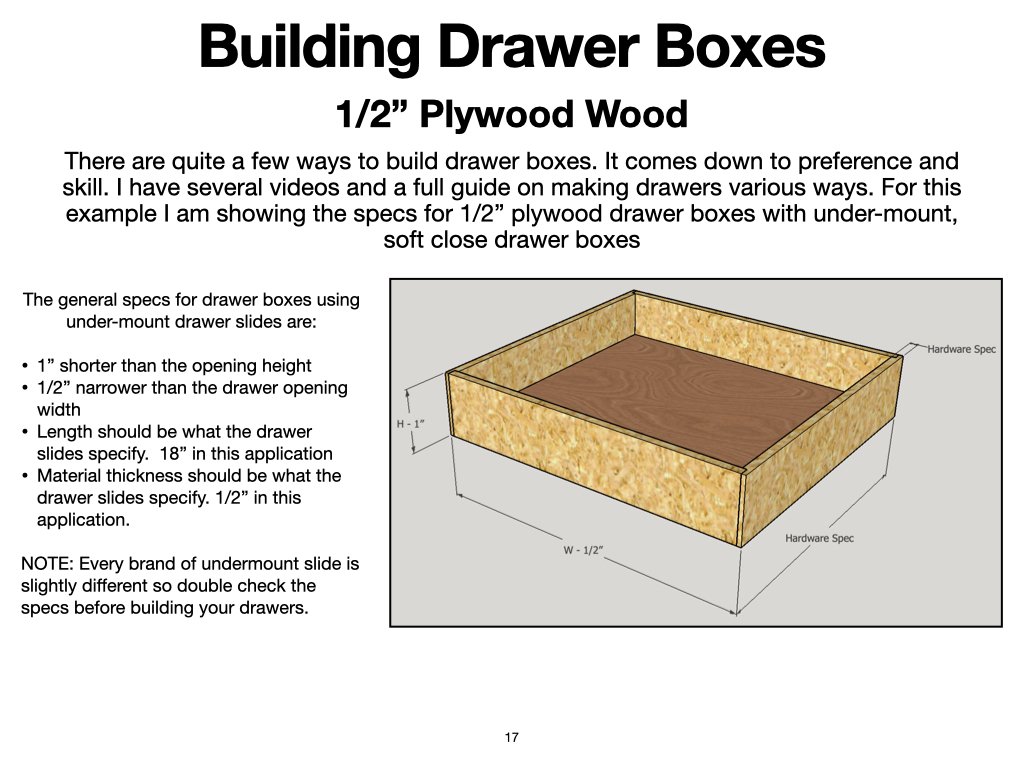

The full material list is included in the plans and consists of two 3/4” sheets of plywood, one 1/2” sheet of plywood, four casters, three sets of drawer slides, piano hinges, and various screws.

My actual cost to build this project with locally available materials was $463.58 (circa 2022). Prices will vary based on your area, and price fluctuations based on market conditions.

This project can be completed in a weekend.